You'll revolutionize your industrial chimney inspections with these 10 cutting-edge methods. Aerial drones capture detailed images, while thermal imaging reveals hidden flaws. LiDAR creates accurate 3D models, and ultrasonic testing measures wall thickness. 3D photogrammetry detects structural defects, and robotic crawlers access hard-to-reach areas. High-resolution cameras provide thorough assessments, and infrared thermography spots thermal anomalies. Gas detection sensors guarantee safety, and AI-powered defect recognition enhances accuracy. These technologies greatly boost efficiency, reduce risks, and improve the overall inspection process. Dive deeper to discover how each method can transform your industrial chimney maintenance strategy.

Key Takeaways

- Aerial drone surveys provide quick, cost-effective inspections with high-resolution imaging and thermal detection capabilities.

- Thermal imaging technology analyzes heat distribution to identify structural weaknesses and insulation failures non-invasively.

- LiDAR mapping systems create accurate 3D models of chimneys, enabling virtual inspections and detecting subtle structural changes.

- Ultrasonic thickness testing offers precise measurements of wall thickness to evaluate structural integrity and detect hidden corrosion.

- Robotic crawlers equipped with sensors and cameras can access hard-to-reach areas within chimneys for internal inspections.

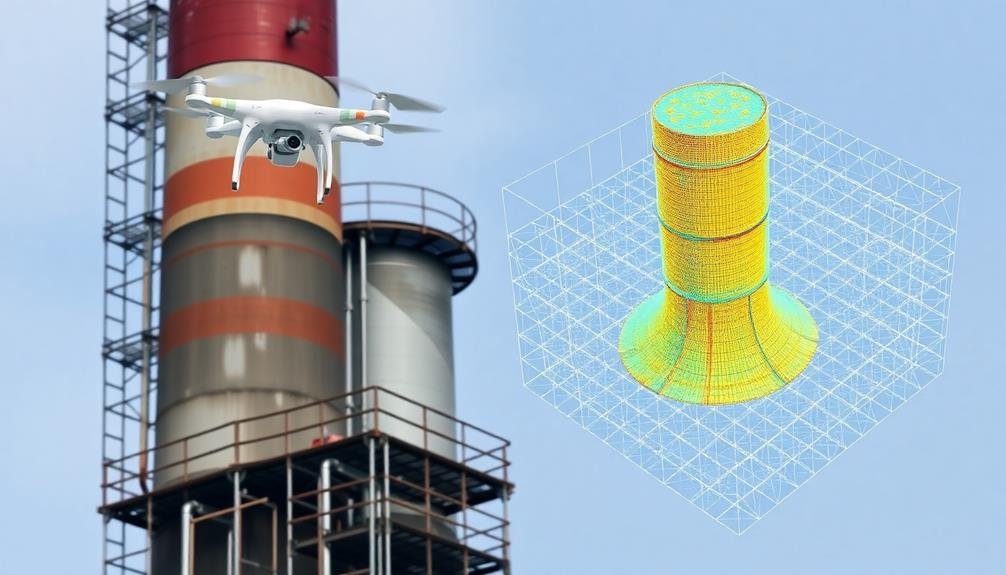

Aerial Drone Surveys

Drones have revolutionized industrial chimney inspections. You'll find these unmanned aerial vehicles equipped with high-resolution cameras and sensors, capable of capturing detailed images and data from previously inaccessible areas. By using drones, you can greatly reduce inspection time and eliminate the need for dangerous manual climbing.

You'll appreciate how drones can quickly survey the entire chimney structure, including hard-to-reach areas like the top and interior. They'll provide you with real-time video feeds and capture high-quality images for later analysis. You can easily detect cracks, corrosion, or structural issues that might be missed during traditional inspections.

With thermal imaging cameras, you'll identify hot spots or insulation problems without shutting down operations. Drones can also measure emissions and collect gas samples, guaranteeing compliance with environmental regulations. You'll save time and money by avoiding scaffolding or cherry picker rentals.

When planning a drone inspection, you'll need to take into account factors like weather conditions, flight regulations, and operator expertise. You should also make sure proper data management and analysis to make the most of the collected information.

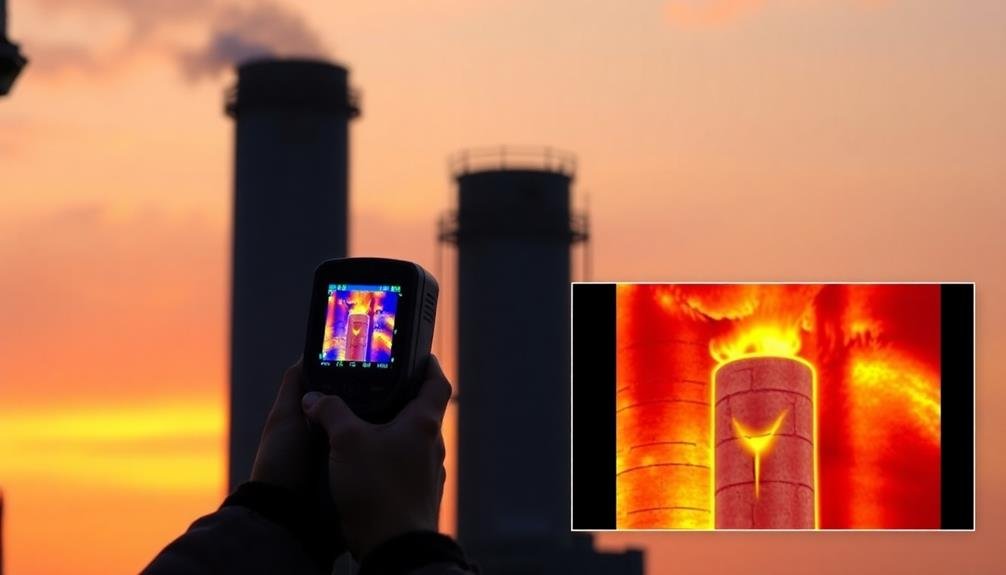

Thermal Imaging Technology

You'll find thermal imaging technology invaluable for industrial chimney inspections.

It allows you to analyze heat distribution patterns, revealing potential issues like insulation failures or structural weaknesses.

You can also use this technology to detect hidden flaws that mightn't be visible to the naked eye, such as internal cracks or areas of excessive wear.

Heat Distribution Analysis

Thermal imaging technology has revolutionized heat distribution analysis in industrial chimney inspections. You'll find that this advanced method allows for a thorough assessment of heat patterns within the chimney structure.

By using thermal cameras, you can detect temperature variations that may indicate potential issues or inefficiencies in the system.

When conducting a heat distribution analysis, you'll be able to:

- Identify hot spots that could signal structural weaknesses

- Detect areas of heat loss, indicating insulation problems

- Locate blockages or restrictions in the flue

- Assess the overall efficiency of the chimney's heat transfer

You'll notice that thermal imaging provides real-time, non-invasive insights into the chimney's performance. This technology enables you to pinpoint areas of concern quickly and accurately, saving time and resources in the inspection process.

Detecting Hidden Flaws

Building on the heat distribution analysis, thermal imaging technology's applications extend far beyond temperature mapping. You'll find it's an invaluable tool for detecting hidden flaws in industrial chimneys. By capturing infrared radiation, thermal cameras can reveal issues invisible to the naked eye.

You can use this technology to identify:

| Flaw Type | Detection Method | Potential Consequences |

|---|---|---|

| Cracks | Temperature variations | Structural instability |

| Moisture infiltration | Cool spots | Corrosion and deterioration |

| Insulation gaps | Heat loss patterns | Reduced efficiency |

| Refractory damage | Hotspots | Safety hazards |

These hidden flaws, if left unchecked, can lead to significant problems. You'll want to pay close attention to any anomalies in the thermal images, as they often indicate underlying issues. For instance, a crack might appear as a thin line of different temperature, while moisture infiltration shows up as cooler areas.

LiDAR Mapping Systems

LiDAR mapping systems have revolutionized industrial chimney inspections. These advanced tools use laser technology to create highly accurate 3D models of chimneys, both inside and out.

You'll find that LiDAR offers several advantages over traditional inspection methods, including increased safety, faster data collection, and more thorough results.

When you employ LiDAR for chimney inspections, you're able to:

- Capture millions of data points in minutes

- Create detailed 3D models for analysis

- Detect subtle structural changes over time

- Access hard-to-reach areas without scaffolding

LiDAR's precision allows you to identify even minor defects, such as hairline cracks or slight deformations, that might go unnoticed with conventional techniques.

You can use the resulting 3D models to perform virtual inspections, reducing the need for repeated site visits and minimizing downtime.

Ultrasonic Thickness Testing

Ultrasonic thickness testing offers you a powerful tool for evaluating industrial chimney integrity.

You'll gain precise measurements of wall thickness, allowing for accurate appraisal of structural stability.

This method also enables you to detect hidden corrosion and erosion, helping prevent potential failures before they occur.

Precision Thickness Measurement

When it comes to evaluating the structural integrity of industrial chimneys, precision thickness measurement is an essential step. You'll find that ultrasonic thickness testing is the go-to method for this task. It's non-destructive, accurate, and provides real-time results.

Using high-frequency sound waves, you can measure the thickness of chimney walls without causing any damage. The ultrasonic device sends sound pulses through the material and measures the time it takes for the echo to return. This allows you to:

- Detect areas of wall thinning or corrosion

- Identify potential weak spots before they become critical

- Monitor changes in thickness over time

- Guarantee compliance with safety regulations

You'll need to calibrate your equipment properly and select the right transducer for the material you're testing.

It's essential to take multiple readings at various points along the chimney's height and circumference to get a thorough picture of its condition.

Corrosion Detection Capabilities

One of the most valuable aspects of ultrasonic thickness testing is its ability to detect corrosion in industrial chimneys. You'll find this method particularly effective in identifying areas of material loss due to chemical reactions, erosion, or other degradation processes.

By sending high-frequency sound waves through the chimney's walls, you can accurately measure remaining wall thickness and pinpoint areas of concern.

With ultrasonic testing, you're able to detect both uniform and localized corrosion. Uniform corrosion appears as an overall thinning of the chimney walls, while localized corrosion manifests as pits or small areas of significant material loss.

You'll appreciate the method's sensitivity, which allows you to identify even minor corrosion in its early stages.

This non-destructive technique enables you to map corrosion patterns across the entire chimney structure. You'll be able to create detailed corrosion profiles, highlighting areas that require immediate attention or more frequent monitoring.

3D Photogrammetry Techniques

Numerous industrial chimney inspections now employ advanced photogrammetry techniques to create detailed 3D models. You'll find that these methods offer significant advantages over traditional inspection approaches. By capturing multiple high-resolution images from various angles, you can generate accurate digital representations of the chimney structure.

The process involves using specialized cameras and software to stitch together the images, creating a thorough 3D model. This technique allows you to:

- Detect structural defects with high precision

- Measure dimensions and assess deformations

- Document the chimney's condition over time

- Analyze hard-to-reach areas without physical access

You'll appreciate the efficiency of photogrammetry in reducing inspection time and costs. It's particularly useful for tall chimneys or those with limited access points. The resulting 3D models serve as valuable tools for maintenance planning and decision-making.

When implementing photogrammetry techniques, you'll need to take into account factors such as lighting conditions, camera positioning, and image overlap. Proper execution guarantees the creation of accurate, detailed models that can reveal even minor defects or changes in the chimney's structure.

This technology continues to evolve, offering increasingly sophisticated analysis capabilities for industrial chimney inspections.

Gas Detection Sensors

Gas detection sensors play an essential role in ensuring safety during industrial chimney inspections. These devices detect the presence of harmful gases, alerting inspectors to potential hazards before they become life-threatening.

You'll find various types of sensors used in chimney inspections, including electrochemical, infrared, and catalytic bead sensors.

When you're conducting an inspection, you'll want to use gas detectors that can identify multiple gases simultaneously. Common gases monitored include carbon monoxide, sulfur dioxide, and nitrogen oxides.

Modern sensors often feature real-time data logging and wireless connectivity, allowing you to track gas levels over time and share information instantly with your team.

You'll need to calibrate your gas detection sensors regularly to maintain accuracy. It's vital to follow manufacturer guidelines for calibration frequency and procedures.

Don't forget to check the sensors' battery life before each inspection, as a dead battery could leave you vulnerable to unseen dangers.

Robotic Crawlers for Internal Inspections

Robotic crawlers have revolutionized internal chimney inspections, allowing you to access hard-to-reach areas safely and efficiently.

These sophisticated devices can navigate complex chimney structures, including bends, narrow passages, and vertical climbs.

As the crawler moves through the chimney, it transmits real-time data and high-resolution images, giving you immediate insights into the structure's condition.

Navigating Complex Chimney Structures

Industrial chimney inspections often require maneuvering through complex internal structures that are challenging for human inspectors to access safely. Robotic crawlers have revolutionized this process, allowing for thorough examinations of even the most intricate chimney designs.

These advanced machines are equipped with various sensors and cameras, enabling them to traverse and document the condition of flues, baffles, and other internal components.

When you're using robotic crawlers for complex chimney inspections, you'll find they offer several advantages:

- Ability to access tight spaces and narrow passages

- Real-time video feed for immediate analysis

- Precise measurements and data collection

- Reduced safety risks for human personnel

You'll need to evaluate the specific design of each chimney when selecting the appropriate crawler. Some models are better suited for vertical ascents, while others excel at traversing horizontal sections or irregular surfaces.

You can program these robots to follow predetermined paths or control them remotely, adapting to unexpected obstacles or areas of interest. By leveraging these high-tech tools, you'll guarantee a thorough inspection of even the most complex industrial chimneys, identifying potential issues before they become critical problems.

Real-Time Data Transmission

One of the most significant advantages of using robotic crawlers for internal chimney inspections is their ability to transmit data in real-time. As you control the crawler remotely, you'll receive instant feedback on the chimney's condition, allowing for immediate analysis and decision-making. This real-time capability enables you to identify critical issues promptly and adjust the inspection focus as needed.

The crawler's advanced sensors and cameras capture high-resolution images and video, which are instantly relayed to your monitoring station. You'll see detailed views of the chimney's interior, including cracks, corrosion, or other structural problems. Additionally, the crawler can measure parameters like temperature, pressure, and gas composition, providing a thorough assessment of the chimney's performance.

Real-time data transmission also enhances safety by reducing the need for human entry into hazardous environments. You can guide the crawler through complex structures while remaining in a safe location.

This technology allows for more frequent and thorough inspections, as you can easily schedule and conduct them without extensive preparation or downtime. By leveraging real-time data, you'll improve the efficiency and effectiveness of your industrial chimney inspection process.

High-Resolution Camera Systems

With advancements in technology, high-resolution camera systems have become an indispensable tool for industrial chimney inspections. These systems provide you with detailed, high-quality images of the chimney's interior, allowing for thorough assessments of its condition.

You'll be able to identify even the smallest cracks, corrosion, or structural issues that might otherwise go unnoticed.

Modern high-resolution cameras offer several advantages for chimney inspections:

- Enhanced zoom capabilities for close-up views of specific areas

- Wide-angle lenses to capture a broader perspective of the chimney's interior

- Low-light performance for clear imaging in dimly lit conditions

- High frame rates to capture smooth video footage during inspections

You can now use these camera systems in conjunction with drones or robotic crawlers, enabling access to hard-to-reach areas of the chimney.

This combination considerably reduces the need for human inspectors to physically enter dangerous spaces.

By utilizing high-resolution camera systems, you'll improve the accuracy and efficiency of your inspections while minimizing safety risks.

The detailed visual data collected can be used for extensive reports, allowing for better-informed decisions regarding maintenance and repairs.

Infrared Thermography Analysis

As part of an extensive inspection strategy, infrared thermography analysis stands out as a powerful non-destructive testing method. It allows you to detect thermal anomalies in industrial chimneys without physical contact. You'll use specialized infrared cameras to capture heat signatures, revealing hidden issues like insulation gaps, refractory damage, or hot spots.

When you're conducting an infrared scan, you'll focus on temperature variations across the chimney's surface. These variations can indicate potential problems such as structural weaknesses, gas leaks, or areas of excessive wear. You'll need to interpret the thermal images carefully, considering factors like ambient temperature and time of day.

One of the key advantages you'll find with infrared thermography is its ability to identify issues before they become visible to the naked eye. This early detection can save you significant time and money on repairs.

You'll also appreciate how quickly you can survey large areas of the chimney, making it an efficient inspection method.

To get the most out of infrared analysis, you should combine it with other inspection techniques. This multi-faceted approach will give you a thorough understanding of your chimney's condition.

AI-Powered Defect Recognition

AI-powered defect recognition is revolutionizing industrial chimney inspections. This cutting-edge technology uses machine learning algorithms to analyze images and data collected during inspections, identifying potential issues with unprecedented accuracy and speed.

You'll find that AI can detect subtle defects that might be missed by human inspectors, improving the overall safety and efficiency of industrial chimneys.

By implementing AI-powered defect recognition in your inspection process, you're able to:

- Analyze large volumes of inspection data quickly

- Detect early signs of wear and tear before they become major problems

- Reduce human error and subjectivity in defect identification

- Prioritize maintenance tasks based on severity and urgency

The system works by comparing inspection images to a vast database of known defects, allowing it to identify issues such as cracks, corrosion, and structural weaknesses.

You'll receive detailed reports highlighting areas of concern, complete with recommended actions. This technology not only saves time and resources but also enhances the longevity and safety of industrial chimneys.

As AI continues to advance, you can expect even more sophisticated defect recognition capabilities in the future.

Frequently Asked Questions

How Often Should Industrial Chimneys Be Inspected?

You should inspect industrial chimneys annually at minimum. However, you'll need more frequent inspections if you're dealing with harsh conditions or high-risk operations. It's essential you follow local regulations and manufacturer recommendations for your specific chimney type.

What Safety Certifications Are Required for Industrial Chimney Inspection Personnel?

You'll need OSHA safety certifications, including fall protection training. You should also obtain confined space entry and aerial lift operation certifications. Don't forget specialized chimney inspection training from organizations like CSIA or NACS for industry-specific knowledge.

Can Inspections Be Conducted While the Chimney Is in Operation?

You can conduct some inspections while the chimney's in operation, but it's limited. You'll need to contemplate safety risks, heat, and emissions. It's often better to schedule inspections during planned shutdowns for thorough assessments.

How Long Does a Comprehensive Industrial Chimney Inspection Typically Take?

You'll find that a thorough industrial chimney inspection typically takes 1-3 days. It depends on the chimney's size, complexity, and accessibility. You should factor in time for preparation, data analysis, and report writing too.

What Are the Cost Differences Between Traditional and Cutting-Edge Inspection Methods?

You'll find cutting-edge methods often cost more initially but save money long-term. They're faster, more accurate, and reduce downtime. Traditional methods are cheaper upfront but may miss issues, leading to costly repairs later. Consider your budget and needs carefully.

In Summary

You've now explored cutting-edge methods for industrial chimney inspections. These technologies offer safer, more efficient, and more accurate ways to assess chimney conditions. By embracing these innovations, you'll improve your inspection processes and catch potential issues earlier. Don't hesitate to incorporate these advanced techniques into your maintenance routines. They'll save you time, money, and reduce risks associated with traditional inspection methods. Stay ahead of the curve and guarantee your chimneys remain in top condition.

As educators and advocates for responsible drone use, we’re committed to sharing our knowledge and expertise with aspiring aerial photographers.

Leave a Reply