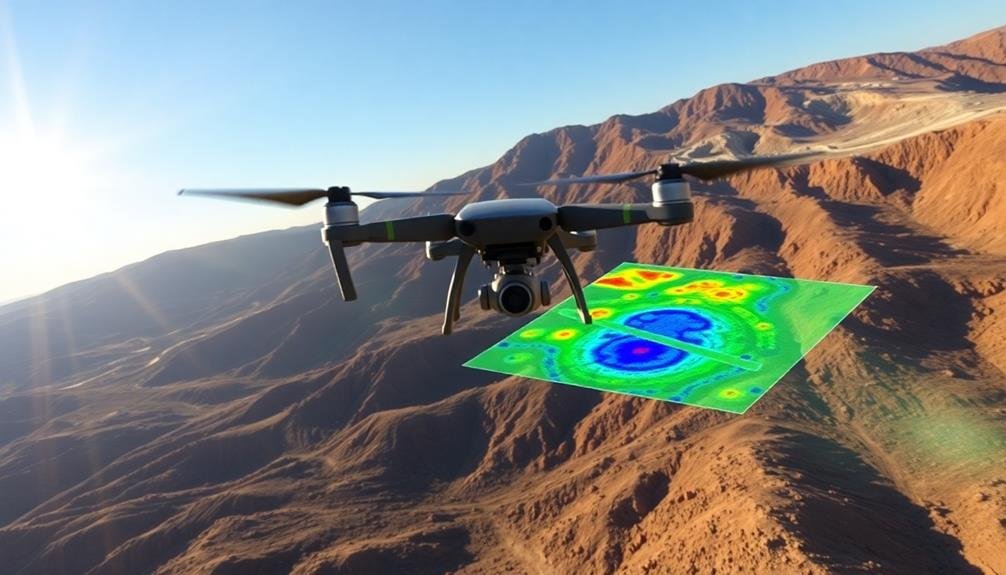

To map mining sites with UAV technology, you'll need to select the right drone equipment, including high-resolution cameras and sensors. Plan your survey mission carefully, optimizing flight paths and setting up ground control points. Collect data using appropriate flight patterns with proper image overlap. Process the aerial imagery using photogrammetry software to create detailed 3D models and orthomosaic maps. Integrate this data with GIS for thorough analysis. Confirm regulatory compliance by obtaining necessary certifications and following operational guidelines. By leveraging UAV technology, you'll achieve rapid, cost-effective, and safe mapping of mining sites. Exploring these steps further will reveal even more potential for your mapping projects.

Benefits of UAV Mining Site Mapping

UAV technology's integration into mining site mapping has revolutionized the industry. You'll find that using drones for surveying offers numerous advantages over traditional methods.

First, you can collect data more quickly and efficiently, covering large areas in a fraction of the time it would take ground-based teams. This speed translates to cost savings and increased productivity.

You'll also benefit from enhanced safety measures. UAVs can access dangerous or hard-to-reach areas without putting personnel at risk, reducing workplace accidents and liability concerns.

The high-resolution imagery and 3D models produced by drones provide more accurate and detailed information about your mining site's topography, allowing for better planning and decision-making.

Additionally, you'll appreciate the ability to monitor site progress regularly and easily. Frequent UAV surveys enable you to track changes over time, detect potential issues early, and optimize operations.

The data collected can be used for volume calculations, stockpile management, and environmental impact assessments. By integrating UAV technology into your mining operations, you'll improve overall efficiency, reduce costs, and gain valuable insights into your site's dynamics.

Choosing the Right Drone Equipment

When selecting drone equipment for mining site mapping, you'll need to take into account several key factors.

First, evaluate the camera and sensor options to guarantee they meet your imaging and data collection requirements.

Next, assess the flight time capabilities of different models to match your site's size and mapping needs, and don't forget to factor in the payload capacity necessary for your chosen sensors and equipment.

Camera and Sensor Options

Selecting the right camera and sensors for your drone is vital to successful mining site mapping. You'll need to take into account factors like resolution, spectral bands, and data processing capabilities. High-resolution RGB cameras are imperative for creating detailed orthomosaic maps and 3D models. For more advanced applications, multispectral or hyperspectral sensors can provide valuable data on mineral composition and vegetation health.

| Sensor Type | Applications | Considerations |

|---|---|---|

| RGB Camera | Orthomosaic mapping, 3D modeling | Resolution, frame rate |

| Multispectral | Mineral detection, vegetation analysis | Spectral bands, calibration |

| LiDAR | Accurate terrain modeling, volumetric calculations | Range, point cloud density |

When choosing your camera setup, take into account the specific requirements of your mining operation. If you're focusing on stockpile measurements, a high-resolution RGB camera paired with LiDAR might be ideal. For exploration purposes, a multispectral sensor could help identify potential mineral deposits. Don't forget to factor in the drone's payload capacity and flight time when selecting sensors. You'll also need to verify your ground control station has sufficient processing power to handle the data collected by these sensors. By carefully matching your camera and sensor options to your mapping objectives, you'll maximize the effectiveness of your UAV mapping efforts.

Flight Time Considerations

Flight time stands out as an essential factor when choosing the right drone for mining site mapping.

You'll need to take into account the size of the area you're surveying and the level of detail required. Larger sites or those needing high-resolution imagery will demand longer flight times. Most consumer-grade drones offer 20-30 minutes of flight time, which may be inadequate for extensive mining operations.

For extended missions, look for drones with longer battery life or the ability to swap batteries quickly. Some professional-grade UAVs can fly for up to an hour, allowing you to cover more ground in a single session.

You might also take into account drones with automated battery replacement systems for continuous operation.

Weather conditions can greatly affect flight time. Strong winds, extreme temperatures, and high altitudes can drain batteries faster.

Plan your missions with these factors in mind, and always carry spare batteries. If your project requires multiple flights, factor in time for battery recharging or replacement between sessions.

Payload Capacity Requirements

Payload capacity is an essential factor in choosing the right drone for mining site mapping. You'll need to evaluate the weight of the sensors and cameras required for accurate data collection. Most mapping drones should carry at least a high-resolution camera and, often, additional sensors like LiDAR or multispectral cameras.

For basic mapping, a drone with a payload capacity of 500g to 1kg may suffice. This allows for a quality camera and potentially a small LiDAR sensor. However, if you're planning more complex surveys or need to carry multiple sensors, you'll want to look at drones with higher payload capacities, ranging from 2kg to 5kg or more.

Remember that increased payload capacity often comes at the cost of flight time. You'll need to balance these factors based on your specific mapping needs.

Evaluate the size of your mining site and the level of detail required in your surveys. If you're mapping large areas or need highly detailed data, opt for a drone with a higher payload capacity to accommodate more sophisticated equipment.

Always factor in the weight of any additional accessories, such as gimbal systems or protective casings, when calculating your total payload requirements.

Planning Your UAV Survey Mission

When planning your UAV survey mission, you'll need to focus on flight path optimization to guarantee extensive coverage of the mining site.

You should design an efficient route that captures all necessary data while minimizing flight time and battery usage.

Don't forget to establish ground control points throughout the survey area to enhance the accuracy of your mapping results and provide reference markers for data processing.

Flight Path Optimization

For successful UAV mapping of mining sites, refining your flight path is crucial. You'll need to take into account factors like terrain, obstacles, and the specific data you're aiming to collect. Start by analyzing the site's topography and identifying potential hazards that could interfere with your drone's flight.

When designing your flight path, focus on efficiency and coverage. You'll want to guarantee that your UAV captures high-quality data while minimizing flight time and battery usage. Think about using a grid or lawn mower pattern for systematic coverage, adjusting the flight altitude and camera settings as needed for peak resolution.

To maximize the effectiveness of your flight path:

- Use waypoints to guide your drone through complex terrain or around obstacles.

- Incorporate overlap in your image capture to ascertain complete coverage and facilitate accurate data stitching.

- Plan for multiple flights if necessary, dividing large areas into manageable sections.

Remember to account for weather conditions and lighting when planning your flight path. Wind direction and speed can affect your drone's performance, while shadows and glare can impact image quality.

Ground Control Points

While optimizing your flight path is important, it's equally essential to establish accurate ground control points (GCPs) for your UAV survey mission. GCPs are precisely surveyed markers on the ground that serve as reference points for your aerial imagery. They're vital for ensuring the accuracy and reliability of your final map.

To set up GCPs, you'll need to strategically place markers across your survey area. These markers should be easily visible from the air and contrast with the surrounding terrain. Use a high-precision GPS device to record the exact coordinates of each GCP. Aim to distribute GCPs evenly throughout the site, paying special attention to the corners and edges of your survey area.

The number of GCPs you'll need depends on the size of your mining site and the desired accuracy of your map. As a general rule, include at least five GCPs for small areas and add more for larger sites.

Remember to document each GCP's location and take clear, close-up photos for later reference. By investing time in setting up accurate GCPs, you'll greatly enhance the quality and precision of your UAV-generated mining site map.

Data Collection and Flight Patterns

In the domain of UAV-based mining site mapping, effective data collection and flight patterns are essential for accurate results. You'll need to plan your flight mission carefully, considering factors like terrain, obstacles, and desired resolution.

Start by determining the area you want to cover and the level of detail required for your project. When planning your flight pattern, opt for a grid or lawn mower pattern to guarantee thorough coverage. Adjust your flight altitude based on the desired ground sampling distance (GSD) and the capabilities of your drone's camera.

Remember to maintain consistent overlap between images, typically 70-80% front overlap and 60-70% side overlap, to guarantee proper stitching during processing.

Consider these key points for successful data collection:

- Choose appropriate weather conditions with minimal wind and good lighting

- Set your camera to manual mode for consistent exposure across all images

- Use a fixed focal length to maintain image consistency

During the flight, monitor your drone's battery life and be prepared to pause and resume the mission if necessary.

After completing the flight, review the collected data to guarantee you've captured all required areas and that image quality meets your standards.

Processing and Analyzing Aerial Imagery

Having collected your aerial imagery, the next essential step is processing and analyzing the data. Begin by importing your raw images into specialized photogrammetry software. This software will stitch together the individual photos to create a thorough orthomosaic map and 3D model of the mining site.

During processing, you'll need to correct for any distortions caused by the UAV's movement or camera angle. Apply georeferencing techniques to guarantee your map aligns accurately with real-world coordinates.

Once processed, you can start analyzing the imagery for valuable insights. Use GIS tools to identify and measure key features such as excavation areas, stockpiles, and equipment locations. You can calculate volumes, track changes over time, and assess the overall progress of mining operations.

Look for signs of erosion, vegetation encroachment, or potential safety hazards. Advanced analysis techniques might include spectral analysis to detect mineral deposits or environmental impacts.

Machine learning algorithms can help automate feature detection and classification. Remember to verify your findings with ground-truth data whenever possible, and always interpret results within the context of your specific mining site's characteristics and operational goals.

Creating 3D Models of Mining Sites

Thanks to advances in UAV technology and photogrammetry software, you can now create highly detailed 3D models of mining sites. These models offer an extensive view of the terrain, allowing you to analyze topography, measure volumes, and plan operations with unprecedented accuracy.

To create a 3D model, you'll need to process the aerial images captured by your UAV using specialized software. Start by importing your georeferenced images into the photogrammetry software. The program will then align the photos and generate a sparse point cloud. Next, it'll create a dense point cloud, which forms the basis of your 3D model. From this, you can generate a mesh and add texture for a more realistic representation.

Key benefits of 3D models for mining sites include:

- Accurate volumetric calculations for stockpiles and excavations

- Improved site planning and design

- Enhanced safety through better visualization of hazards

Once you've created your 3D model, you can use it for various applications. You'll be able to take precise measurements, create contour maps, and even simulate different scenarios for mine planning.

These models also serve as valuable historical records, allowing you to track changes in the site over time.

Integrating UAV Data With GIS

Building on the power of 3D models, integrating UAV data with Geographic Information Systems (GIS) takes your mining site analysis to the next level. This integration allows you to combine aerial imagery, topographic data, and other geospatial information into a thorough digital representation of your mining operation.

To integrate UAV data with GIS, you'll need to process the raw data collected by your drone. Start by georeferencing your aerial images, which assigns real-world coordinates to each pixel.

Next, use photogrammetry software to create orthomosaics and digital elevation models (DEMs) from your UAV imagery. Once you've processed your data, import it into your GIS software.

You can overlay your orthomosaics and DEMs with existing GIS layers, such as property boundaries, geological maps, and infrastructure layouts. This combination allows you to perform advanced spatial analysis, including volume calculations, slope analysis, and site planning.

Regulatory Compliance for Drone Operations

Maneuvering through the regulatory landscape is vital when operating drones for mining site mapping. You'll need to comply with local, state, and federal regulations to guarantee your operations are legal and safe.

Begin by obtaining the necessary certifications, such as a Remote Pilot Certificate from the FAA if you're in the United States. Familiarize yourself with airspace restrictions and obtain proper authorizations for flying in controlled airspace.

Before each flight, you must conduct a thorough pre-flight checklist, including weather conditions, battery levels, and equipment functionality. Always maintain visual line of sight with your drone and respect privacy laws when capturing images.

It's imperative to keep detailed flight logs and maintain your equipment to guarantee compliance and safety.

Key regulatory considerations include:

- Registering your drone with the appropriate authorities

- Adhering to weight limits and operational restrictions

- Following specific rules for commercial drone operations

Stay updated on changing regulations, as drone laws evolve rapidly. Consider joining professional organizations or forums to stay informed about best practices and regulatory updates.

Frequently Asked Questions

How Long Does It Take to Train a Drone Operator for Mining Surveys?

You'll typically need 2-4 weeks of intensive training to become a proficient drone operator for mining surveys. This includes learning regulations, flight skills, and specialized mapping software. Ongoing practice is essential for maintaining expertise.

What Are the Typical Costs Associated With Implementing UAV Technology for Mining?

You'll need to budget for the drone itself ($2,000-$20,000), software licenses ($1,000-$5,000 annually), training ($2,000-$5,000 per operator), and ongoing maintenance. Don't forget insurance costs and potential regulatory fees for commercial use.

Can UAVS Be Used for Underground Mine Mapping or Only Surface Operations?

While UAVs are primarily used for surface mapping, you can use specialized underground drones for confined spaces. They're equipped with LiDAR, thermal sensors, and obstacle avoidance systems to navigate and map tunnels and caverns effectively.

How Often Should UAV Surveys Be Conducted to Maintain Accurate Site Data?

You should conduct UAV surveys regularly, ideally every 1-3 months. However, the frequency depends on your site's activity level, changes in topography, and data needs. For rapidly evolving sites, weekly surveys may be necessary.

Are There Any Environmental Concerns or Impacts When Using Drones for Mining Surveys?

You should consider potential wildlife disturbance, noise pollution, and vegetation damage when using drones for mining surveys. There's also the risk of soil erosion if you're frequently landing drones in the same areas.

In Summary

You've now got the tools to revolutionize your mining site mapping with UAV technology. By selecting the right equipment, planning effectively, and following best practices for data collection and analysis, you'll create accurate 3D models and integrate seamlessly with GIS. Don't forget to stay compliant with regulations. With these skills, you're ready to enhance safety, efficiency, and decision-making in your mining operations. Embrace this cutting-edge approach and watch your productivity soar.

As educators and advocates for responsible drone use, we’re committed to sharing our knowledge and expertise with aspiring aerial photographers.

Leave a Reply