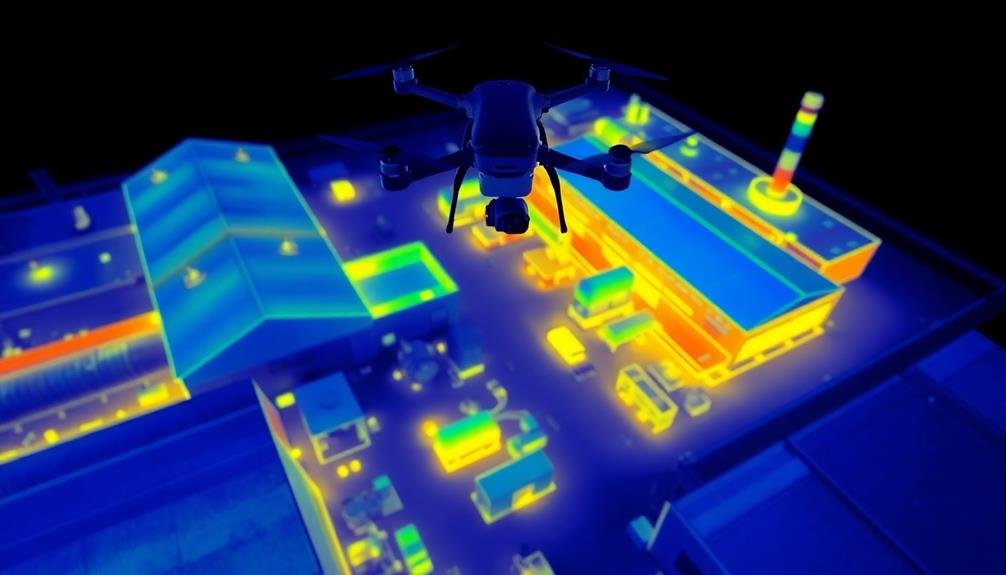

For factory inspections, you'll find several outstanding aerial thermal imaging solutions. The DJI Mavic 2 Enterprise Advanced offers high-resolution thermal imaging with extended flight time. FLIR Vue Pro R provides radiometric capabilities for precise temperature measurements. Parrot Anafi Thermal combines compact design with dual-sensor functionality. Yuneec H520E and Autel EVO II Dual offer robust features for outdoor inspections. For long-range performance, consider the Sensefly eBee X or DJI Zenmuse XT2. The Workswell WIRIS Pro and Teledyne FLIR Duo Pro R excel in advanced thermal imaging. Each solution brings unique advantages to enhance your factory inspection process. Explore further to discover which option best suits your specific needs.

Key Takeaways

- High-resolution thermal cameras, like DJI Mavic 2 Enterprise Advanced and FLIR Vue Pro R, offer detailed factory inspections.

- Extended flight time drones, such as Matrice 300 RTK and Sensefly eBee X, enable comprehensive coverage of large facilities.

- Dual-sensor systems, like Autel EVO II Dual and Teledyne FLIR Duo Pro R, combine thermal and visual imaging for enhanced analysis.

- Compact and portable designs, exemplified by the Anafi Thermal, allow for easy transport and quick deployment in factory settings.

- Advanced features like RTK positioning, MSX technology, and customizable temperature alarms improve inspection accuracy and issue identification.

DJI Mavic 2 Enterprise Advanced

One of the most versatile thermal imaging drones on the market, the DJI Mavic 2 Enterprise Advanced offers exceptional capabilities for factory inspections. This compact drone combines a high-resolution visual camera with a radiometric thermal camera, allowing you to capture detailed images and videos in both spectrums simultaneously.

The thermal camera boasts a 640×512 resolution, providing crisp thermal imagery for identifying hot spots, insulation issues, or equipment malfunctions in your factory. With a temperature range of -4°F to 752°F, you'll detect a wide variety of thermal anomalies. The 48MP visual camera guarantees you can capture clear, detailed images for documentation and analysis.

You'll appreciate the drone's portability, with its foldable design making it easy to transport and deploy quickly. The Mavic 2 Enterprise Advanced offers up to 31 minutes of flight time, giving you ample opportunity to inspect large factory areas in a single flight.

Its obstacle avoidance system and RTK module assure precise, safe navigation in complex industrial environments. With features like spot meter and area measurement, you can easily quantify temperature data on-site.

The drone's IP44 rating also means it can operate in light rain and dusty conditions, enhancing its versatility for various factory inspection scenarios.

FLIR Vue Pro R

You'll find the FLIR Vue Pro R to be an exceptional thermal imaging solution for your factory inspections.

It offers high-resolution thermal imaging and radiometric data capture, allowing you to collect precise temperature measurements for each pixel.

This versatile camera integrates seamlessly with various drone platforms, enhancing your aerial inspection capabilities.

High-Resolution Thermal Imaging

The FLIR Vue Pro R stands at the forefront of high-resolution thermal imaging technology for aerial factory inspections. With its advanced sensors and precision optics, you'll capture detailed thermal images that reveal hidden issues in your factory infrastructure. This camera offers a range of resolution options, allowing you to choose the best fit for your specific inspection needs.

You'll appreciate the Vue Pro R's ability to detect minute temperature variations, which is essential for identifying potential equipment failures or energy inefficiencies. Its high frame rates guarantee smooth, real-time imaging even during rapid drone movements, giving you a clear view of your entire facility.

| Resolution | Frame Rate | Field of View |

|---|---|---|

| 640 x 512 | 30 Hz | 45° x 35° |

| 336 x 256 | 60 Hz | 35° x 27° |

| 640 x 512 | 9 Hz | 69° x 56° |

The camera's radiometric capabilities allow you to perform accurate temperature measurements, which is invaluable for preventive maintenance and safety assessments. You can easily integrate the Vue Pro R with your existing drone systems, thanks to its compatibility with various platforms. By leveraging this high-resolution thermal imaging solution, you'll enhance the efficiency and effectiveness of your factory inspection processes.

Radiometric Data Capture

Precision is the hallmark of the FLIR Vue Pro R's radiometric data capture capabilities. You'll find this feature indispensable for factory inspections, as it allows you to measure temperature accurately at every pixel in your thermal images.

With radiometric data, you're not just seeing heat patterns; you're quantifying them. The Vue Pro R captures and stores temperature data for each pixel, enabling you to perform detailed post-flight analysis. You can identify exact temperature values, set temperature thresholds, and create extensive thermal reports.

This level of detail is essential for pinpointing potential issues in factory equipment, electrical systems, or insulation. You'll appreciate the flexibility the radiometric data offers. It allows you to adjust parameters like emissivity and reflected temperature after the flight, ensuring accurate temperature readings across various surfaces and materials.

The Vue Pro R's compatibility with common thermal analysis software streamlines your workflow, making it easier to interpret and share your findings.

Versatile Drone Integration

Compatibility is at the core of the FLIR Vue Pro R's design, making it a versatile choice for various drone platforms. You'll find that this thermal camera seamlessly integrates with popular drones like DJI, Yuneec, and custom-built UAVs. Its compact size and lightweight construction guarantee it won't compromise your drone's flight performance or battery life.

The Vue Pro R features standard mounting options, including GoPro-style mounts, which allow for quick and easy installation on most drones. You can also adjust the camera's position mid-flight, thanks to its compatibility with various gimbals and stabilization systems.

For more advanced setups, the camera offers multiple interface options. You'll appreciate its ability to connect directly to your drone's flight controller, enabling real-time data overlay and precise geotag information. The MAVLink protocol support further enhances its integration capabilities, allowing for seamless communication with your drone's telemetry systems.

When you're planning factory inspections, you can count on the Vue Pro R to work with your existing drone fleet or easily adapt to new platforms as your needs evolve. This flexibility guarantees you're always equipped with the right thermal imaging solution for your specific inspection requirements.

Parrot Anafi Thermal

You'll find the Parrot Anafi Thermal drone equipped with advanced thermal imaging capabilities, perfect for detailed factory inspections.

Its compact and portable design allows you to easily transport and deploy it in various industrial settings.

With long-range flight performance, you can cover extensive areas efficiently, capturing thermal data from hard-to-reach locations in your facility.

Advanced Thermal Imaging Capabilities

Harnessing cutting-edge technology, the Parrot Anafi Thermal drone delivers advanced thermal imaging capabilities for factory inspections.

You'll benefit from its dual-sensor camera system, which combines a 4K HDR camera with a FLIR Lepton 3.5 radiometric thermal sensor. This setup allows you to capture both visible light and thermal images simultaneously, providing thorough data for your inspections.

The drone's thermal imaging resolution of 160×120 pixels enables you to detect temperature variations as small as 0.1°C. You can choose from various color palettes to visualize heat signatures, making it easier to identify potential issues in factory equipment or infrastructure.

The Anafi Thermal's ability to measure temperatures ranging from -10°C to 400°C guarantees you can assess a wide variety of industrial environments.

With the FreeFlight 6 app, you'll have access to advanced features like adjustable emissivity settings and isotherms. These tools help you fine-tune your thermal analysis and pinpoint areas of concern more accurately.

The drone's 4x digital zoom allows you to inspect hard-to-reach areas without compromising image quality, while its compact design guarantees maneuverability in tight spaces.

Compact and Portable Design

The Parrot Anafi Thermal's compact and portable design sets it apart in the world of industrial drone inspections. Weighing just 315 grams, this lightweight drone is easy to transport and deploy in various factory settings.

You'll appreciate its foldable structure, which allows you to pack it into a small carrying case, making it ideal for on-the-go inspections. The drone's slim profile enables it to navigate tight spaces within factory environments, accessing areas that larger drones can't reach.

Its compact size doesn't compromise on performance, as it still offers a 26-minute flight time and a range of up to 4 km. This allows you to cover extensive factory areas in a single flight.

You'll find the Anafi Thermal's portability particularly useful when conducting routine inspections across multiple sites. Its quick setup time means you can start inspecting within minutes of arriving at a location.

The drone's design also incorporates a 180-degree tiltable camera, giving you the flexibility to capture thermal images from various angles without repositioning the entire aircraft. This feature proves invaluable when inspecting complex machinery or hard-to-reach areas in factory settings.

Long-Range Flight Performance

While the Anafi Thermal's compact design facilitates easy transport, its long-range flight performance truly shines in factory inspection scenarios.

You'll appreciate its ability to cover large areas efficiently, with a maximum flight time of up to 26 minutes on a single battery charge. This extended flight duration allows you to inspect expansive factory facilities without frequent landings or battery swaps.

The drone's range is equally impressive, with a maximum transmission distance of 4 km. This long-range capability enables you to inspect hard-to-reach areas or tall structures without compromising image quality or control.

The Anafi Thermal's flight performance isn't just about distance, though. It can withstand wind speeds of up to 50 km/h, ensuring stable flight and clear thermal imaging even in challenging weather conditions.

You'll find the drone's intelligent flight modes particularly useful for factory inspections. Features like automated flight paths and waypoint navigation allow you to create repeatable inspection routes, ensuring consistent coverage of critical areas.

The Anafi Thermal's precise hovering capabilities also come in handy when you need to focus on specific points of interest during your inspection, providing steady, detailed thermal imagery for accurate analysis.

Yuneec H520E With E10T

You'll find the Yuneec H520E paired with the E10T thermal camera to be a powerful combination for aerial factory inspections. This hexacopter drone offers industrial-grade performance with its robust design and advanced features.

The E10T camera provides high-resolution thermal imaging, allowing you to detect heat anomalies in equipment, electrical systems, and building structures.

The H520E boasts a flight time of up to 28 minutes, giving you ample time to cover large factory areas. Its obstacle avoidance system guarantees safe navigation around complex industrial environments.

You'll appreciate the drone's ability to withstand winds up to 39 mph, making it suitable for outdoor inspections in various weather conditions.

The E10T camera's 640×512 thermal resolution delivers crisp, detailed thermal images. It's equipped with a radiometric sensor, enabling you to measure precise temperature values for each pixel.

This feature is essential for identifying potential issues in machinery or electrical systems before they lead to costly failures.

The Yuneec DataPilot™ software enhances your inspection capabilities with automated flight planning and data analysis tools.

You can create precise flight paths, guaranteeing thorough coverage of your factory facilities and generating detailed inspection reports efficiently.

Autel EVO II Dual

You'll find the Autel EVO II Dual particularly useful for factory inspections due to its dual-sensor camera system.

This drone combines a high-resolution visual camera with a thermal imaging sensor, allowing you to capture both visible and infrared data simultaneously.

With its extended flight time, you can cover larger areas or conduct more thorough inspections without frequent battery changes.

Dual-Sensor Camera System

In light of advanced thermal imaging needs, the Autel EVO II Dual stands out with its dual-sensor camera system. This innovative setup combines a high-resolution visible light camera with a thermal imaging sensor, giving you the best of both worlds for factory inspections.

The visible light camera boasts a 48MP resolution, allowing you to capture incredibly detailed images of your facility's exterior and interior. You'll be able to spot even the tiniest structural issues or potential hazards.

The thermal sensor, on the other hand, operates at 640×512 resolution, providing you with clear heat signatures of equipment, electrical systems, and other critical components.

What sets this dual-sensor system apart is its ability to overlay thermal data onto visible light images. This feature lets you easily identify and locate heat anomalies within the context of your factory's layout.

You can switch between visible, thermal, and picture-in-picture modes on the fly, adapting to different inspection scenarios.

The Autel EVO II Dual's camera system also offers adjustable parameters for both sensors, ensuring you can fine-tune your inspections for ideal results.

With this versatile tool, you'll enhance the efficiency and accuracy of your factory inspections considerably.

Extended Flight Time

When it comes to aerial factory inspections, extended flight time is essential for thorough coverage. The Autel EVO II Dual offers an impressive 40-minute flight time, allowing you to capture more footage and thermal data in a single mission. This extended duration means you'll spend less time swapping batteries and more time gathering vital information about your factory's infrastructure.

With the EVO II Dual's long-lasting battery, you can:

- Cover larger areas without interruption

- Perform multiple inspection tasks in one flight

- Capture time-lapse thermal data for extensive analysis

- Reduce overall inspection time and operational costs

You'll appreciate the efficiency gains from fewer battery changes and minimal downtime. The extended flight time also enables you to conduct more detailed inspections, as you can hover longer at specific points of interest without worrying about battery life.

This feature is particularly valuable for complex factory layouts or when investigating hard-to-reach areas. The EVO II Dual's extended flight time, combined with its dual-sensor capabilities, makes it an excellent choice for factory inspectors who need to maximize their time in the air and gather extensive thermal and visual data efficiently.

Matrice 300 RTK With H20T

The Matrice 300 RTK paired with the H20T camera is a powerful duo for aerial thermal imaging in factory inspections. This combination offers you unparalleled versatility and precision in thermal data collection.

The Matrice 300 RTK drone boasts a flight time of up to 55 minutes, allowing you to cover large factory areas in a single mission. Its robust design withstands harsh industrial environments, while its RTK positioning system guarantees centimeter-level accuracy.

The H20T camera is a game-changer for thermal inspections. It features a 640×512 radiometric thermal sensor, providing high-resolution thermal images for detailed analysis. You'll appreciate its 20x optical zoom and 200x max zoom, enabling you to inspect hard-to-reach areas without compromising image quality.

The camera also includes a 20MP visual sensor and a laser rangefinder, giving you extensive data in a single flight.

With the Matrice 300 RTK and H20T, you can efficiently detect heat anomalies, identify equipment issues, and monitor energy efficiency in factories. The system's AI-powered smart inspection tools streamline your workflow, automatically identifying and tracking objects of interest.

This combination considerably reduces inspection time and improves the accuracy of your thermal imaging results.

Sensefly Ebee X With Thermomap

Another contender in the aerial thermal imaging arena, the Sensefly eBee X paired with the Thermomap sensor offers a unique solution for factory inspections. This fixed-wing drone system combines efficiency with high-quality thermal imaging capabilities, making it ideal for large-scale industrial applications.

The eBee X's lightweight design allows for extended flight times, covering vast areas in a single mission. When equipped with the Thermomap sensor, you'll benefit from precise thermal data collection, enabling you to identify heat anomalies and potential issues in your factory infrastructure.

Key features of the Sensefly eBee X with Thermomap include:

- Long flight time of up to 90 minutes

- Ability to cover up to 500 hectares in a single flight

- High-resolution thermal imagery with 0.1°C thermal sensitivity

- Seamless integration with data processing software for quick analysis

You'll appreciate the eBee X's ease of use, as it can be operated by a single person and doesn't require a specialized launch or landing area.

The system's automated flight planning and execution guarantee consistent data collection, while its durability makes it suitable for various weather conditions.

With the Sensefly eBee X and Thermomap combination, you'll have a powerful tool for thorough factory inspections and preventive maintenance.

DJI Zenmuse XT2

Stepping into the spotlight of thermal imaging technology, DJI's Zenmuse XT2 offers a powerful solution for factory inspections. This dual-sensor camera combines a high-resolution thermal imager with a 4K visual camera, providing you with extensive data for your industrial inspections.

The XT2's advanced features include:

| Feature | Benefit | Application |

|---|---|---|

| FLIR Tau 2 thermal core | High sensitivity | Detect subtle temperature variations |

| 12MP visual camera | Clear daytime imagery | Identify structural issues |

| IP44 ingress protection | Weather resistance | Operate in various conditions |

| Isotherms | Highlight temperature ranges | Pinpoint potential problems |

| Temperature alarm | Real-time alerts | Immediate issue notification |

You'll appreciate the XT2's ability to switch between thermal and visual feeds seamlessly. Its MSX technology overlays visual details onto thermal images, enhancing clarity and context. With a 9Hz or 30Hz frame rate, you can capture smooth footage of moving machinery or conveyor belts.

The XT2 integrates seamlessly with DJI's enterprise drones, making it an ideal choice for factory inspections. You'll find its temperature measurement accuracy and radiometric capabilities invaluable for identifying hotspots, detecting equipment malfunctions, and ensuring workplace safety.

Workswell WIRIS Pro

While DJI's Zenmuse XT2 offers impressive capabilities, Workswell's WIRIS Pro takes thermal imaging for factory inspections to new heights. This advanced system combines high-resolution thermal and visual cameras, providing you with unparalleled insights into your facility's operations.

The WIRIS Pro's standout features include:

- Dual-sensor setup with a 640×512 thermal resolution and 1920×1080 visible light camera

- Temperature range of -40°C to 2000°C, ideal for detecting overheating equipment

- Customizable temperature alarms and isotherms for real-time issue identification

- Radiometric video recording for detailed post-inspection analysis

You'll appreciate the WIRIS Pro's user-friendly interface, which allows for quick adjustments and easy interpretation of thermal data. Its robust construction guarantees reliability in harsh industrial environments, while its compatibility with various drone platforms offers flexibility in deployment.

The system's advanced software suite enables you to create detailed inspection reports, complete with thermal overlays and temperature measurements. This feature streamlines your documentation process and helps you communicate findings effectively to stakeholders.

With the Workswell WIRIS Pro, you're equipped to conduct thorough, efficient factory inspections that identify potential issues before they escalate into costly problems.

Teledyne FLIR Duo Pro R

The Teledyne FLIR Duo Pro R stands out as a versatile and powerful thermal imaging solution for factory inspections. This dual-sensor camera combines high-resolution thermal imaging with a 4K visible light camera, giving you extensive data for your inspections.

You'll appreciate the Duo Pro R's ability to capture both thermal and visible images simultaneously, allowing for easy comparison and analysis. With its 640 x 512 thermal resolution and 4K visible light camera, you'll get crisp, detailed images that help you identify potential issues quickly.

The camera's MSX technology enhances thermal images by overlaying key visible details, improving your ability to interpret the data. You can choose from various color palettes to highlight temperature differences effectively.

The Duo Pro R is compatible with most drone platforms, making it easy to integrate into your existing setup. Its compact size and lightweight design won't greatly impact your drone's flight time or maneuverability.

You'll find the intuitive controls and onboard recording capabilities particularly useful during inspections. The camera's radiometric capabilities allow you to measure temperatures accurately, helping you pinpoint areas of concern in your factory environment.

Frequently Asked Questions

How Often Should Thermal Imaging Inspections Be Conducted in Factories?

You should conduct thermal imaging inspections in factories at least annually. However, it's best to perform them quarterly for critical equipment. You'll want to increase frequency for high-risk areas or if you've had recent issues.

What Training Is Required to Operate Thermal Imaging Drones Effectively?

You'll need training in drone piloting, thermal imaging technology, and data interpretation. It's vital to learn safety protocols, regulations, and camera operation. Hands-on practice and understanding thermal patterns are essential for effective thermal imaging drone operation.

Can Thermal Imaging Drones Detect Gas Leaks in Industrial Settings?

Yes, you can use thermal imaging drones to detect gas leaks in industrial settings. They'll spot temperature differences caused by escaping gases. You'll need the right sensors and know-how to interpret the images effectively.

How Do Weather Conditions Affect the Accuracy of Aerial Thermal Imaging?

Weather conditions considerably impact your aerial thermal imaging accuracy. You'll find rain, wind, and extreme temperatures can distort readings. Sunlight and humidity also affect results. It's best to conduct surveys in stable, moderate weather for ideal accuracy.

Are There Any Legal Restrictions on Using Drones for Factory Inspections?

You'll need to check local regulations, as drone use for inspections may require permits or certifications. Some areas restrict drone flights near buildings or industrial zones. Always comply with FAA rules and obtain necessary permissions.

In Summary

You've now explored some of the top aerial thermal imaging solutions for factory inspections. Whether you're looking for compact drones or advanced camera systems, there's an option to fit your needs. Remember to take into account factors like resolution, flight time, and software compatibility when making your choice. With these cutting-edge tools at your disposal, you'll be able to conduct more efficient and accurate inspections, improving safety and productivity in your facility.

As educators and advocates for responsible drone use, we’re committed to sharing our knowledge and expertise with aspiring aerial photographers.

Leave a Reply