To keep your obstacle sensors in top shape, clean them regularly and inspect for damage. Update firmware promptly and store sensors properly when not in use. Perform calibration checks and consider environmental factors affecting performance. Verify sensor alignment and maintain batteries as needed. Prevent signal interference by proper positioning and shielding. Stick to a professional servicing schedule for ideal longevity. Don't forget to train users on proper handling and care. By following these tips, you'll guarantee your sensors remain reliable and effective. Dive deeper into each strategy to maximize your sensor's lifespan and performance.

Key Takeaways

- Perform regular visual inspections and cleaning with appropriate materials to maintain sensor performance.

- Conduct monthly calibration checks and monitor for any drift in readings.

- Keep firmware and software up-to-date, following manufacturer instructions for installation and testing.

- Protect sensors from environmental factors and physical damage with proper shielding and placement.

- Schedule professional servicing at least annually and maintain detailed records of all maintenance activities.

Regular Cleaning and Inspection

To keep your obstacle sensors in peak condition, you'll need to stay on top of regular cleaning and inspection. Start by establishing a routine maintenance schedule based on your sensor's manufacturer recommendations and usage frequency. At least once a week, visually inspect the sensors for any signs of damage, loose connections, or debris accumulation.

Use a soft, lint-free cloth to gently wipe down the sensor's surface, removing dust, dirt, and other particles that can interfere with its performance. For stubborn grime, lightly dampen the cloth with distilled water or a specialized sensor cleaning solution. Be careful not to use harsh chemicals or abrasive materials that could damage the sensor's delicate components.

Check the sensor's mounting brackets and fasteners to confirm they're secure and properly aligned. Verify that all cables and connectors are firmly attached and free from wear or corrosion. If you notice any issues during your inspection, address them promptly to prevent further damage or sensor malfunction.

Don't forget to test your sensors after each cleaning session. Run a quick calibration check to confirm they're operating within the expected parameters.

Firmware Updates

While regular cleaning and inspection are vital for physical maintenance, keeping your obstacle sensors' software up-to-date is equally important. Firmware updates play a significant role in guaranteeing your sensors operate at peak performance and remain compatible with your system's latest features.

To stay on top of firmware updates, first, enable automatic update notifications on your device or system. This way, you'll be alerted whenever new firmware becomes available. When you receive an update notification, don't delay. Schedule the update for a time when your system isn't in use to avoid disruptions.

Before initiating the update, back up your current settings and configurations. This precaution allows you to revert to a known working state if any issues arise during the update process.

When you're ready, follow the manufacturer's instructions carefully to install the new firmware.

After the update, test your obstacle sensors thoroughly to verify they're functioning correctly. Check for improved performance, new features, or bug fixes mentioned in the update notes.

If you encounter any problems, contact the manufacturer's support team promptly for assistance.

Proper Storage Practices

Proper storage practices for obstacle sensors are essential in maintaining their longevity and performance. When you're not using your sensors, store them in a cool, dry place away from direct sunlight and extreme temperatures. Moisture and heat can damage the sensitive components, so avoid leaving them in damp or hot environments.

Keep your sensors in their original packaging or a protective case when not in use. This will shield them from dust, debris, and accidental impacts. If you're storing multiple sensors, don't stack them on top of each other to prevent pressure damage. Instead, arrange them side by side or in separate compartments.

Before storing, clean your sensors thoroughly using a soft, lint-free cloth. Don't use harsh chemicals or abrasive materials that could scratch the sensor's surface.

If you're storing the sensors for an extended period, remove any batteries to prevent corrosion. For rechargeable sensors, make certain they're partially charged before storage to maintain battery health.

Label your storage containers clearly with the sensor type and any relevant information. This will help you quickly identify and retrieve the right sensor when needed.

Regularly inspect stored sensors for signs of damage or degradation, and test them before use.

Calibration Checks

Beyond proper storage, regular calibration checks are essential to maintaining your obstacle sensors' accuracy. These checks guarantee your sensors are detecting objects at the correct distances and angles.

Start by setting up a controlled environment with known obstacles at specific distances. Compare the sensor readings to these known measurements, and look for any discrepancies.

You'll want to perform calibration checks at least once a month, or more frequently if you're using the sensors in harsh conditions. Pay attention to any drift in readings over time, as this can indicate a need for recalibration or even replacement.

Don't forget to check the sensor's field of view and response time during these tests.

If you notice any inconsistencies, consult your sensor's manual for specific recalibration procedures. Some sensors allow for user calibration, while others may require professional servicing.

Keep a log of your calibration checks and any adjustments made. This record will help you track your sensor's performance over time and anticipate when it might need replacement.

Environmental Considerations

When maintaining your obstacle sensors, you'll need to take into account environmental factors that can affect their performance.

Ascertain your sensor systems are properly weather-proofed to withstand various conditions like rain, snow, or extreme temperatures.

You should also implement measures to protect against dust and debris accumulation, which can impair sensor accuracy and longevity.

Weather-Proofing Sensor Systems

Environmental factors pose significant challenges to obstacle sensor systems, necessitating robust weather-proofing measures. To protect your sensors from the elements, start by guaranteeing proper sealing. Use high-quality, weather-resistant materials like silicone or rubber gaskets to create a watertight seal around sensor housings. This will prevent moisture ingress, which can lead to corrosion and electrical failures.

Consider applying a hydrophobic coating to sensor lenses and external surfaces. This will repel water droplets and prevent fog buildup, maintaining clear sensor vision in wet conditions. For areas prone to extreme temperatures, invest in sensors with built-in temperature regulation systems or add external heating and cooling elements to maintain ideal operating conditions.

Don't forget about dust and debris protection. Install protective covers or shields that can be easily removed for maintenance. Regular cleaning is vital; use compressed air or soft brushes to remove accumulated particles without damaging sensitive components.

In snowy regions, incorporate defrosting mechanisms to prevent ice formation on sensor surfaces. Finally, implement a routine inspection schedule to catch and address any weather-related wear and tear before it compromises sensor performance. By taking these precautions, you'll guarantee your obstacle sensors remain reliable in various weather conditions.

Dust and Debris Protection

Nearly every outdoor environment presents challenges in the form of dust and debris for obstacle sensors. To maintain ideal performance, you'll need to implement effective protection strategies. Start by selecting sensors with appropriate IP (Ingress Protection) ratings for your specific environment. Higher IP ratings offer better protection against dust and water intrusion.

Install protective covers or housings designed to shield sensors from direct exposure to dust and debris. These should allow for proper sensor functionality while preventing particulate accumulation. Regularly clean sensor surfaces using compressed air, soft brushes, or microfiber cloths to remove any built-up debris. For stubborn dirt, use a mild cleaning solution recommended by the manufacturer.

Consider implementing automated cleaning systems, such as air jets or wipers, for sensors in particularly dusty environments. These can help maintain cleanliness between manual maintenance sessions.

Position sensors strategically to minimize exposure to dust sources, and use deflectors or baffles to redirect airflow and reduce particle accumulation.

Establish a routine inspection and cleaning schedule based on your operating conditions. This proactive approach will help you identify potential issues early and maintain consistent sensor performance.

Avoiding Physical Impact

Safeguarding obstacle sensors from physical damage is crucial for maintaining their functionality. To protect these essential components, you'll need to be proactive and mindful of potential hazards.

When parking or maneuvering in tight spaces, be extra cautious to avoid bumping into objects that could strike the sensors. If your vehicle has protruding sensors, take care when driving through areas with low-hanging branches or debris.

During maintenance or cleaning, handle the sensors gently and avoid applying excessive pressure. If you're using automated car washes, opt for touchless systems to minimize the risk of damage.

When installing accessories or modifying your vehicle, verify that you don't interfere with the sensors' positioning or field of view.

Be aware of your surroundings when driving in challenging conditions, such as off-road or in areas with construction. Rocks, gravel, or other debris kicked up by your tires can potentially damage sensors.

If you're towing or carrying large loads, double-check that the cargo doesn't obstruct or come into contact with the sensors.

Sensor Alignment Verification

Over time, even well-protected sensors can become misaligned, potentially compromising their effectiveness. To guarantee your obstacle sensors are functioning at their best, you'll need to verify their alignment regularly. Start by consulting your device's manual for specific alignment procedures, as they can vary between models.

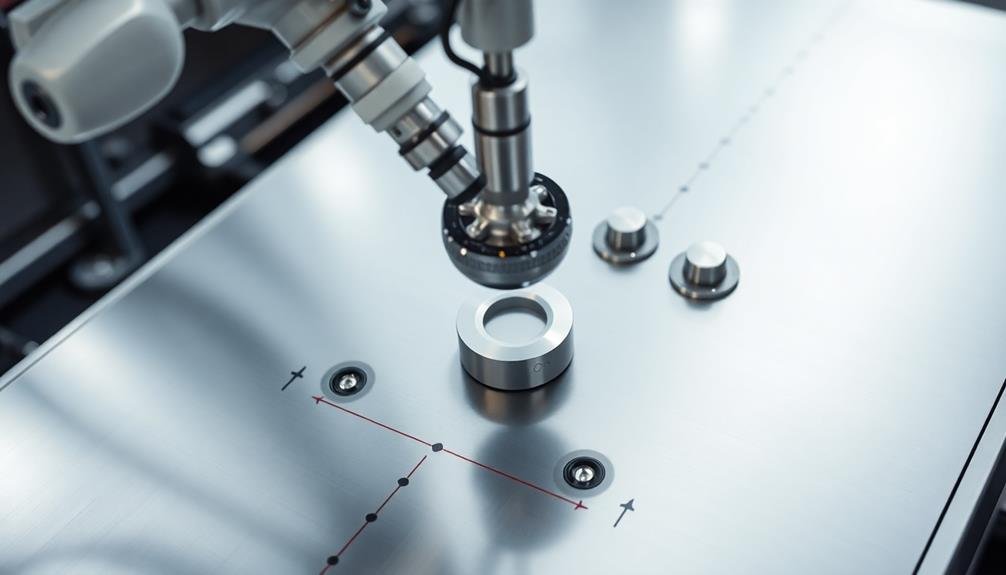

You can perform a basic alignment check by placing a flat, reflective surface at a known distance from the sensor. Measure the sensor's output and compare it to the expected reading. If there's a significant discrepancy, you may need to adjust the sensor's position or calibrate it.

Here's a quick guide to common alignment issues and their solutions:

| Issue | Solution |

|---|---|

| Sensor tilted | Adjust mounting bracket |

| Dirty lens | Clean with microfiber cloth |

| Loose connection | Tighten cables and connectors |

| Software drift | Recalibrate using manufacturer's software |

| Physical damage | Replace sensor |

Remember to check alignment after any impact or vibration event. For critical applications, consider implementing an automated alignment verification system to guarantee continuous, reliable operation of your obstacle sensors.

Battery Maintenance

Maintaining your obstacle sensor's battery is essential for guaranteeing uninterrupted operation. You'll want to check the battery level regularly and recharge or replace it as needed. Most modern sensors have built-in indicators that show the current charge level, so make it a habit to glance at these before each use.

To extend battery life, avoid exposing your sensor to extreme temperatures. Heat can degrade battery performance, while cold can temporarily reduce capacity. When not in use, store your sensor in a cool, dry place.

If you're using rechargeable batteries, follow the manufacturer's guidelines for charging cycles to maximize their lifespan. Keep the battery contacts clean by gently wiping them with a dry cloth or electronics-safe cleaning solution. Dirty contacts can lead to poor connections and unreliable performance.

If you're using disposable batteries, remove them when storing the sensor for extended periods to prevent leakage and corrosion. For sensors with sealed internal batteries, pay attention to their expected lifespan and plan for replacement or servicing before they fail.

Signal Interference Prevention

To prevent signal interference in your obstacle sensors, you'll need to implement effective electromagnetic shielding techniques.

Proper sensor placement is essential, ensuring they're away from potential sources of interference. You should also minimize nearby electronics that could disrupt sensor signals, maintaining a clean electromagnetic environment for peak performance.

Electromagnetic Shielding Techniques

Electromagnetic interference can wreak havoc on obstacle sensors, compromising their accuracy and reliability. To protect your sensors from these disruptive forces, you'll need to implement effective electromagnetic shielding techniques.

Start by identifying potential sources of interference in your sensor's environment, such as power lines, motors, or other electronic devices.

Once you've pinpointed the threats, you can apply various shielding methods:

- Use conductive enclosures: Surround your sensors with metal casings or conductive coatings to deflect electromagnetic waves.

- Install ferrite cores: Attach these to cables to suppress high-frequency noise and reduce signal degradation.

- Employ shielded cables: Opt for cables with built-in shielding to minimize electromagnetic pickup during signal transmission.

- Implement grounding techniques: Confirm proper grounding of your sensor system to divert unwanted currents away from sensitive components.

Don't forget to regularly test your shielding effectiveness using specialized equipment.

You should also consider the placement of your sensors, keeping them away from known sources of interference whenever possible.

Proper Sensor Placement

While shielding techniques offer robust protection, proper sensor placement is equally important for preventing signal interference. You'll want to position your obstacle sensors strategically to minimize exposure to potential sources of electromagnetic interference.

First, identify common interference sources in your environment, such as power lines, motors, or other electronic devices. Place sensors as far away from these sources as possible while maintaining their effectiveness.

Consider mounting sensors on non-conductive materials to reduce the risk of coupling with nearby metal structures. When installing multiple sensors, maintain adequate spacing between them to prevent cross-talk.

Follow the manufacturer's guidelines for minimum separation distances. If you're using different types of sensors, arrange them in a way that minimizes overlapping detection zones.

Don't forget about external factors. Shield sensors from direct sunlight and extreme temperatures, as these can affect their performance. In outdoor applications, protect sensors from rain, dust, and debris using appropriate enclosures.

Regularly inspect sensor placement and adjust as needed. Environmental changes or equipment modifications may necessitate repositioning to maintain peak performance.

Minimize Nearby Electronics

A critical step in preventing signal interference is minimizing nearby electronics. Your obstacle sensors rely on clear signals to function properly, so it's important to keep other electronic devices at a safe distance. This includes smartphones, tablets, and even other sensors that might be part of your setup.

To effectively minimize electronic interference:

- Place sensors at least 12 inches away from other electronic devices

- Use shielded cables to connect sensors to your main control unit

- Avoid running sensor wires parallel to power cables

- Consider using ferrite beads on sensor cables to reduce high-frequency noise

Remember that electromagnetic fields can extend beyond what you might expect, so it's best to err on the side of caution.

If you notice inconsistent readings or false positives from your obstacle sensors, nearby electronics could be the culprit. In such cases, try repositioning your sensors or the surrounding devices to see if it resolves the issue.

Professional Servicing Schedule

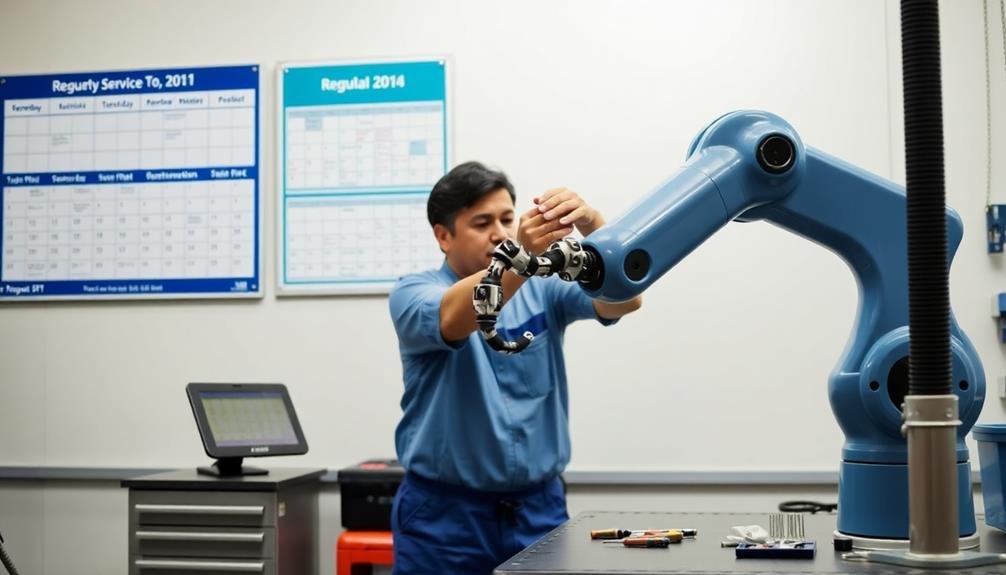

To assure ideal performance of your obstacle sensors, it's crucial to adhere to a professional servicing schedule. Aim to have your sensors professionally inspected and serviced at least once a year, or more frequently if you use them in harsh environments or for critical applications.

During these service appointments, trained technicians will thoroughly clean the sensors, check for any signs of wear or damage, and calibrate them to guarantee optimal accuracy. They'll also update any firmware or software associated with the sensors, keeping them current with the latest improvements and security patches.

Don't wait for problems to arise before scheduling service. Regular maintenance can prevent many issues and extend the lifespan of your sensors. If you notice any changes in sensor performance between scheduled services, don't hesitate to book an additional appointment.

Keep a detailed record of all professional servicing, including dates, procedures performed, and any parts replaced. This log will help you track the sensor's history and identify patterns that might indicate recurring issues or the need for more frequent servicing.

It'll also prove valuable if you ever need to troubleshoot problems or make warranty claims.

Frequently Asked Questions

How Long Do Obstacle Sensors Typically Last Before Needing Replacement?

You'll find obstacle sensors typically last 3-5 years before needing replacement. However, their lifespan can vary based on usage, environment, and maintenance. Regular cleaning and calibration can extend their life. Always check manufacturer recommendations for specific guidance.

Can Obstacle Sensors Be Retrofitted to Older Equipment Models?

You can often retrofit obstacle sensors to older equipment models. It's not always straightforward, but it's possible. You'll need to evaluate compatibility, installation requirements, and potential software updates. Consult with the manufacturer for specific guidance and options.

Are There Specific Certifications Required for Technicians Servicing Obstacle Sensors?

You'll find that certifications for obstacle sensor technicians vary by manufacturer and equipment type. Generally, you'll need specialized training from the sensor's maker or an accredited program. It's best to check with the specific manufacturer for their requirements.

How Do Different Weather Conditions Affect Obstacle Sensor Performance?

You'll find that weather greatly impacts obstacle sensors. Rain and snow can obscure lenses, while extreme temperatures affect sensitivity. Fog and dust reduce detection range. Sunlight glare may cause false readings. Always consider conditions when relying on these sensors.

What Are Common Signs That an Obstacle Sensor Is Malfunctioning?

You'll notice your obstacle sensor's malfunctioning if it's giving false alerts, failing to detect objects, or responding slowly. You might also see error messages on your device's display or experience sudden braking without apparent obstacles.

In Summary

You've now got the know-how to keep your obstacle sensors in peak condition. By following these tips, you'll guarantee your sensors are always ready to perform. Remember, it's not just about maintenance; it's about safety and efficiency. Don't neglect these essential components of your system. Stay proactive, and you'll avoid costly downtime and potential accidents. Keep up with these practices, and you'll maximize your sensors' lifespan and reliability.

As educators and advocates for responsible drone use, we’re committed to sharing our knowledge and expertise with aspiring aerial photographers.

Leave a Reply