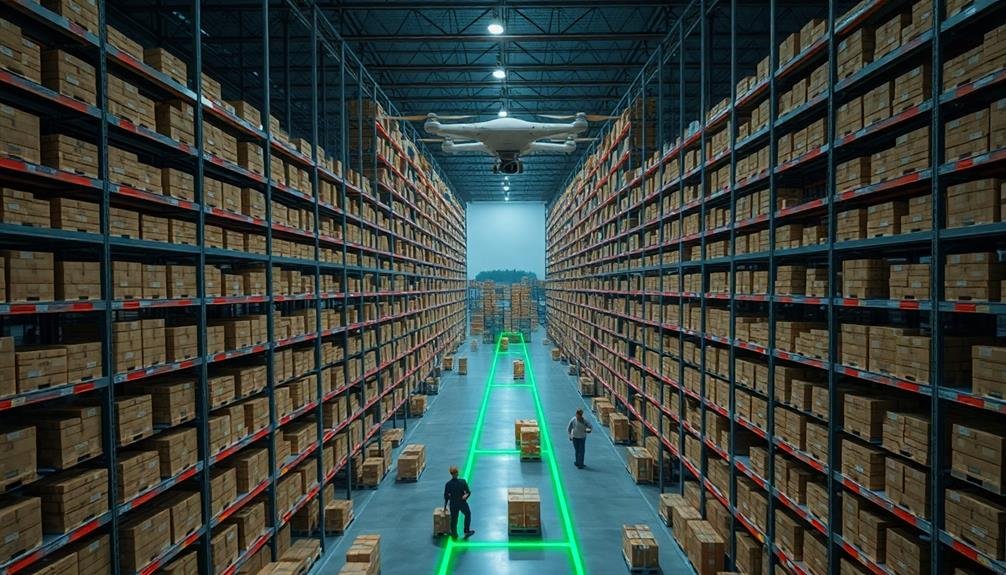

Flying cameras are transforming warehouse inventory management with cutting-edge solutions. You'll find automated stocktaking drones that swiftly scan large areas, real-time tracking systems for up-to-the-minute data, and AI-powered item recognition technology. Barcode scanning from above streamlines processes, while 3D mapping optimizes warehouse layouts. Thermal imaging guarantees proper cold storage, and safety inspections become more thorough. Pallet counting and location verification improve accuracy, and inventory placement strategies get a boost. These innovations enhance efficiency, reduce errors, and increase safety in your warehouse operations. Discover how these top solutions can revolutionize your inventory management approach.

Key Takeaways

- Automated stocktaking with aerial drones reduces manual counting time and improves accuracy in large warehouses.

- Real-time inventory management through drone-captured data enhances decision-making and stock level monitoring.

- AI-powered item recognition technology enables quick detection of misplaced items and labeling errors.

- Barcode scanning drones efficiently cover large areas, accessing hard-to-reach locations and operating during off-hours.

- 3D mapping and thermal imaging capabilities optimize warehouse layout and monitor temperature-sensitive storage areas.

Automated Stocktaking With Aerial Drones

Numerous warehouses are turning to aerial drones for automated stocktaking, revolutionizing inventory management. These flying cameras equipped with advanced sensors and AI technology can quickly scan and record inventory levels across vast storage areas. You'll find that drones markedly reduce the time and labor required for manual counting, improving efficiency and accuracy.

By implementing aerial drone systems, you can conduct regular inventory checks without disrupting daily operations. The drones navigate through narrow aisles and reach high shelves, capturing detailed images and barcodes. This data is then processed in real-time, providing you with up-to-date stock information.

You'll benefit from reduced human error and increased safety, as drones eliminate the need for employees to climb ladders or operate forklifts for inventory counts. Additionally, you can schedule drone flights during off-hours, maximizing warehouse productivity.

The software integration allows you to track inventory trends, identify discrepancies, and optimize stock levels. You'll also appreciate the cost savings from reduced labor and improved inventory accuracy.

As drone technology continues to advance, you can expect even more sophisticated features and capabilities for automated stocktaking in the future.

Real-Time Inventory Tracking Systems

Real-time inventory tracking systems revolutionize warehouse management through cutting-edge technologies.

You'll find automated cycle counting, IoT-enabled stock monitoring, and AI-powered inventory forecasting at the forefront of these advancements.

These integrated solutions provide you with up-to-the-minute data on stock levels, movement patterns, and predictive analytics, enabling more efficient and accurate inventory control.

Automated Cycle Counting

Cutting-edge automated cycle counting systems are revolutionizing warehouse inventory management. These systems use flying cameras to perform regular, systematic counts of inventory without human intervention.

You'll find that these drones can navigate through your warehouse, scanning barcodes and capturing high-resolution images of stock levels. The automated process eliminates human error and reduces the time needed for inventory checks.

You can schedule counts during off-hours, minimizing disruption to daily operations. The system's AI algorithms analyze the data collected, providing you with accurate, up-to-date inventory information.

You'll appreciate the flexibility of automated cycle counting. It allows you to focus on specific areas or products that require more frequent monitoring.

The system can integrate with your existing warehouse management software, ensuring seamless data flow and real-time updates.

IoT-Enabled Stock Monitoring

Implementing IoT-enabled stock monitoring systems transforms your warehouse into a smart, connected environment.

These systems use a network of sensors, RFID tags, and wireless connectivity to provide real-time visibility into your inventory levels and locations.

You'll benefit from accurate, up-to-the-minute data on stock quantities, movements, and conditions.

IoT sensors can monitor temperature, humidity, and vibration, ensuring ideal storage conditions for sensitive goods. They'll alert you to potential issues before they become problems, reducing spoilage and damage.

With IoT-enabled monitoring, you can automate reorder processes, enhance stock levels, and improve demand forecasting.

You'll reduce carrying costs and minimize stockouts by maintaining just the right amount of inventory.

Integration with your warehouse management system allows for seamless data flow and improved decision-making.

You can easily track item history, monitor expiration dates, and generate detailed reports on inventory turnover.

AI-Powered Inventory Forecasting

Artificial intelligence revolutionizes inventory forecasting by leveraging real-time tracking systems. You'll find that AI algorithms can analyze vast amounts of data from flying cameras and IoT sensors to predict future stock needs with remarkable accuracy.

These systems consider factors like historical sales patterns, seasonal trends, and even external variables such as weather or economic indicators.

By implementing AI-powered inventory forecasting, you'll reduce overstock and stockouts, enhancing your warehouse space and cash flow. The system continually learns from new data, improving its predictions over time.

You can set custom parameters and receive alerts when inventory levels are projected to fall below certain thresholds.

AI forecasting also helps you anticipate demand spikes, allowing you to adjust your inventory accordingly. It can suggest ideal reorder points and quantities, taking into account lead times and supplier reliability.

You'll benefit from improved supply chain efficiency and reduced carrying costs.

Moreover, AI can identify slow-moving items and recommend redistribution or discounting strategies. This proactive approach guarantees you're always one step ahead in managing your inventory, maximizing profitability, and meeting customer demands efficiently.

AI-Powered Item Recognition Technology

AI-powered item recognition technology enhances your warehouse's automated inventory scanning capabilities.

You'll experience considerably reduced human error as smart cameras accurately identify and catalog items in real-time.

This advanced system allows you to maintain precise inventory counts and locations, improving overall efficiency and reducing discrepancies.

Automated Inventory Scanning

How can flying cameras revolutionize warehouse inventory management? By implementing automated inventory scanning systems, you'll transform your operations.

These advanced drones equipped with high-resolution cameras and AI technology can swiftly navigate through your warehouse, capturing real-time data on stock levels, product locations, and overall inventory status.

As the drones fly through pre-programmed routes, they'll efficiently scan barcodes, QR codes, or even use image recognition to identify items. This process eliminates the need for manual counting and reduces human error.

You'll benefit from:

- Increased accuracy in inventory tracking

- Reduced labor costs and time spent on stock-taking

- Real-time updates on inventory levels and discrepancies

The automated scanning system integrates seamlessly with your existing warehouse management software, providing instant updates to your inventory database.

You'll have access to extensive reports and analytics, allowing you to make data-driven decisions about restocking, product placement, and overall warehouse optimization.

Reduced Human Error

Through the lens of AI-powered item recognition technology, human error in warehouse inventory management becomes a thing of the past. You'll find that flying cameras equipped with advanced AI algorithms can accurately identify and catalog items with minimal mistakes. This technology greatly reduces discrepancies caused by manual counting or data entry errors.

As you implement this solution, you'll notice a dramatic improvement in inventory accuracy. The AI system can quickly detect misplaced items, incorrect labels, or damaged products that human eyes might miss. You'll also benefit from real-time updates, allowing you to make informed decisions about stock levels and reordering.

| Error Type | Human Method | AI-Powered Method |

|---|---|---|

| Miscounting | Common | Rare |

| Misidentification | Frequent | Minimal |

| Data Entry Mistakes | High Risk | Virtually Eliminated |

Barcode Scanning From Above

Drones equipped with high-resolution cameras are revolutionizing barcode scanning in warehouses. You'll find that these flying cameras can quickly and efficiently scan barcodes from above, eliminating the need for workers to manually scan each item.

This aerial approach allows for a thorough inventory count in a fraction of the time it would take using traditional methods.

With barcode scanning drones, you can:

- Cover large areas of your warehouse in minutes

- Access hard-to-reach places without risking employee safety

- Integrate real-time data into your inventory management system

You'll appreciate the increased accuracy and speed of inventory counts using this technology. Drones can capture multiple barcodes simultaneously, reducing the likelihood of missed items.

They can also operate during off-hours, minimizing disruption to your warehouse operations.

You'll find that implementing barcode scanning drones can greatly improve your inventory management processes. By automating this task, you'll free up your workforce to focus on more complex and value-added activities.

Additionally, you'll have access to more frequent and accurate inventory data, enabling better decision-making and reducing the risk of stockouts or overstocking.

3D Mapping for Warehouse Layout

Revolutionizing warehouse management, 3D mapping technology takes inventory solutions to new heights. You'll find that flying cameras equipped with advanced sensors can create detailed, three-dimensional models of your entire warehouse space. These models provide an extensive view of your facility's layout, helping you optimize storage and improve operational efficiency.

As the drones navigate through your warehouse, they capture high-resolution images and depth data. This information is then processed to generate an accurate 3D map of your facility. You can use this map to identify underutilized spaces, plan more efficient routes for workers and equipment, and even simulate changes to your warehouse layout before implementing them.

The 3D mapping capability also enhances your inventory management. You'll be able to pinpoint the exact location of items within the warehouse, making it easier to track stock levels and locate specific products.

This technology integrates seamlessly with your existing warehouse management systems, providing real-time updates on inventory positions and movements. By leveraging 3D mapping, you'll reduce search times, minimize errors, and streamline your overall warehouse operations, ultimately leading to increased productivity and cost savings.

Integration With Warehouse Management Software

Your warehouse management software's integration with flying camera technology marks a significant leap in inventory control efficiency. By seamlessly connecting these systems, you'll gain access to real-time data updates, automated inventory tracking, and enhanced decision-making capabilities.

The flying cameras capture visual information, which is then processed and fed directly into your existing software platform.

This integration allows you to:

- Automate stock level updates without manual input

- Identify discrepancies between physical and digital inventories instantly

- Generate alerts for low stock or misplaced items

You'll benefit from improved accuracy in your inventory records, as the system continuously cross-references visual data with existing database entries. This reduces human error and provides a more reliable foundation for inventory management decisions.

The integrated system also enables you to track inventory movement patterns over time, helping you optimize warehouse layout and picking routes.

Thermal Imaging for Cold Storage

You'll find thermal imaging capabilities in flying cameras particularly useful for cold storage areas.

These sensors can quickly detect temperature anomalies, alerting you to potential equipment failures or improperly sealed doors.

Temperature Anomaly Detection

Three critical aspects of cold storage management are temperature control, energy efficiency, and product safety.

Flying cameras equipped with thermal imaging capabilities can revolutionize how you detect temperature anomalies in your warehouse. These drones can quickly scan large areas, identifying hot spots or cold pockets that might compromise product integrity.

You'll be able to pinpoint issues before they escalate, saving time and resources. The cameras can detect subtle temperature variations, allowing you to address problems like faulty refrigeration units or poorly insulated areas promptly.

This proactive approach not only guarantees product quality but also helps maintain compliance with strict food safety regulations.

Here are key benefits of using flying cameras for temperature anomaly detection:

- Real-time monitoring and alerts for immediate action

- Extensive coverage of hard-to-reach areas

- Data-driven insights for optimizing energy consumption

Product Freshness Monitoring

Beyond temperature anomaly detection, thermal imaging capabilities of flying cameras offer a powerful tool for monitoring product freshness in cold storage environments.

You can use these advanced drones to scan entire warehouses, identifying areas where products may be at risk of spoilage due to temperature fluctuations or equipment malfunctions.

With thermal imaging, you'll be able to detect subtle temperature differences that could indicate potential issues with your cold storage units. This allows you to take proactive measures to prevent product loss and maintain quality.

You can easily spot warm spots in refrigerated areas, which might suggest a failing compressor or inadequate insulation.

Moreover, you'll gain valuable insights into your cold chain management. By regularly monitoring product temperatures throughout your warehouse, you can guarantee that perishable goods are stored at peak conditions.

This data helps you make informed decisions about inventory rotation and storage practices.

You can also use thermal imaging to verify that your cold storage units are operating efficiently.

Safety Inspections Using Drones

Drones' versatility extends beyond inventory management to revolutionize safety inspections in warehouses. You'll find these flying cameras invaluable for conducting extensive checks of hard-to-reach areas, identifying potential hazards, and ensuring compliance with safety regulations.

By using drones, you can greatly reduce the time and manpower required for inspections while improving the overall safety of your warehouse environment.

With high-resolution cameras and advanced sensors, drones can detect issues that might go unnoticed during manual inspections. They'll help you spot:

- Structural damage to shelving units or support beams

- Faulty wiring or electrical hazards

- Potential fire risks or blocked emergency exits

You can program drones to follow specific inspection routes, ensuring consistent and thorough coverage of your entire facility.

They'll capture detailed imagery and data, which you can analyze in real-time or store for future reference. This approach allows you to address safety concerns promptly and maintain a proactive stance on workplace safety.

Pallet Counting and Location Verification

One of the most critical tasks in warehouse management is accurately counting pallets and verifying their locations. Flying cameras equipped with advanced imaging technology can revolutionize this process, making it faster, more accurate, and less labor-intensive.

You'll find that drones can quickly navigate through your warehouse, capturing high-resolution images of pallet stacks and their locations. These images are then processed using artificial intelligence and machine learning algorithms to count pallets and verify their positions automatically. This method considerably reduces human error and saves time compared to manual counting.

With drone-based pallet counting, you can conduct inventory checks more frequently, guaranteeing your stock levels are always up to date. You'll also be able to identify discrepancies between physical inventory and your warehouse management system more quickly, allowing for prompt investigation and resolution.

Moreover, drones can access hard-to-reach areas and high stacks that might be challenging or dangerous for human workers. This capability guarantees an all-encompassing count of all pallets in your warehouse, regardless of their location.

Optimizing Inventory Placement Strategies

Flying cameras equipped with advanced sensors and AI algorithms can revolutionize your inventory placement strategies. These drones can analyze your warehouse layout and product movement patterns to suggest ideal locations for different items.

By continuously monitoring stock levels and order frequencies, they'll help you implement dynamic slotting, ensuring fast-moving products are always easily accessible.

You'll benefit from real-time data on space utilization, allowing you to maximize storage efficiency and minimize wasted areas. The drones can identify underutilized spaces and recommend reorganization strategies to improve overall warehouse capacity.

They'll also help you implement zone-based storage systems, grouping similar products together for easier picking and reduced travel time.

Enhancing inventory placement with flying cameras offers several advantages:

- Reduced picking times and improved order fulfillment rates

- Decreased labor costs through more efficient warehouse operations

- Enhanced adaptability to seasonal demand fluctuations

Frequently Asked Questions

What Are the Initial Costs Associated With Implementing Flying Camera Inventory Solutions?

You'll face initial costs for drones, cameras, software, and training. You're looking at expenses for hardware setup, system integration, and potential facility modifications. Don't forget to factor in regulatory compliance and insurance costs too.

How Long Does It Take to Train Staff to Operate Drone Systems?

You'll find that training staff for drone operations typically takes 1-2 weeks. It depends on your team's tech-savviness and the system's complexity. Some basic training can be done in a few days, but mastery takes longer.

Are There Any Regulatory Hurdles for Using Drones Indoors for Inventory Management?

You'll face fewer regulatory hurdles using drones indoors for inventory management. However, you'll still need to comply with workplace safety regulations, guarantee proper training, and implement protocols to protect employees and equipment from potential drone-related accidents.

What Backup Systems Are in Place if Flying Cameras Malfunction Mid-Operation?

You'll find backup systems are essential for flying camera operations. You've got redundant batteries, automatic landing protocols, and fail-safe mechanisms. You'll also have manual override options and backup drones ready to take over if needed.

How Do Flying Cameras Handle Inventory in High-Rack or Hard-To-Reach Areas?

You'll find that flying cameras excel in high-rack and hard-to-reach areas. They're designed to navigate tight spaces, using precise controls and obstacle avoidance technology. You can program them to scan vertically, capturing inventory data from all levels.

In Summary

You've seen how flying cameras revolutionize warehouse inventory management. They'll save you time, reduce errors, and boost efficiency. By embracing these cutting-edge solutions, you'll gain real-time insights, improve safety, and optimize your operations. Don't hesitate to explore these technologies further and consider implementing them in your warehouse. The future of inventory management is airborne, and you're now ready to take your operations to new heights.

As educators and advocates for responsible drone use, we’re committed to sharing our knowledge and expertise with aspiring aerial photographers.

Leave a Reply